'Our products are made in Europe, so you can be sure that your diapers were not made by the hands of children.' A frequently heard statement in the reusable diaper industry, which we find quite daring. To blindly assume that there is no child labor in your chain (within the vulnerable textile sector) is to bury your head in the sand. Out of ignorance or fear.

After attending a webinar on child labor a few months ago and listening to several much larger companies than us, we felt a strong urge to want and need to do something about this. Unfortunately, child labor is far from being eradicated, in fact, since the Corona pandemic, unfortunately more children are working again than before. An eerie feeling came over us, a feeling of not being sure at all whether all our products, from the very first step to the final product, are actually guaranteed free of child labor. In fact, perhaps you should assume that children may be employed somewhere in one of those countless chains, far away, at the beginning. Because that is a more helpful thought than hoping that or believing that. And because such a thought paves the way to a solution. And that is where we really want to go.

We decided to investigate it. Months of research followed. We participated in webinars, spoke to experts in the field of child labor and read a lot. We listened with great admiration to Marianne van Keep, Chief Sustainability Officer at Verstegen. At the end of 2021, she received the award for CSR manager of the year. 'No, Verstegen is not free from child labor and that will not happen again in my career. But we are on the right track.' Her courage, openness and decisiveness have inspired us to write this blog for you. No matter how exciting that is. We take you into the grim and complex world of child labor.

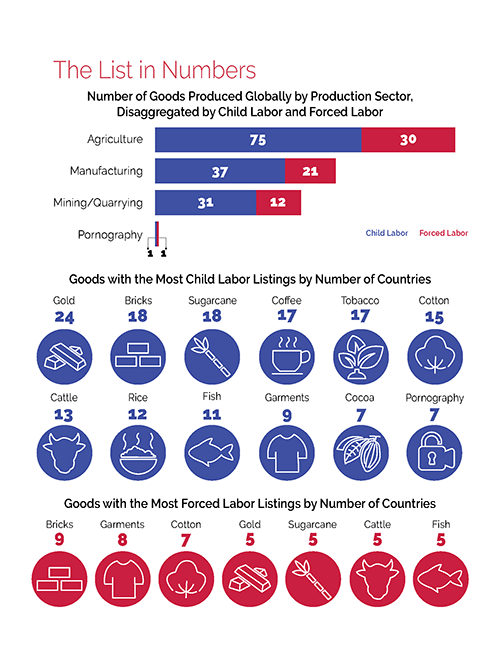

Worldwide, 160 million children aged 5 to 17 work, which is 1 in 10 children. The majority of them work in agriculture, as many as 70% of the children. Of the 160 million child laborers, 79 million children do dangerous work that harms their health and development. A child may work, but first and foremost it must be able to just be a child. Children who do not go to school, but work instead, are called child laborers. Children may only work if they are not too young, the work is not dangerous, unhealthy or forced, and there is sufficient time for education, play and rest. The ILO (International Labor Organization) also divides children into three age groups. According to them, child labor is when children under the age of 12 work, when children between 12 and 14 years old have to do heavy work and when children under the age of 18 have to do dangerous work that could damage the health and safety of children.

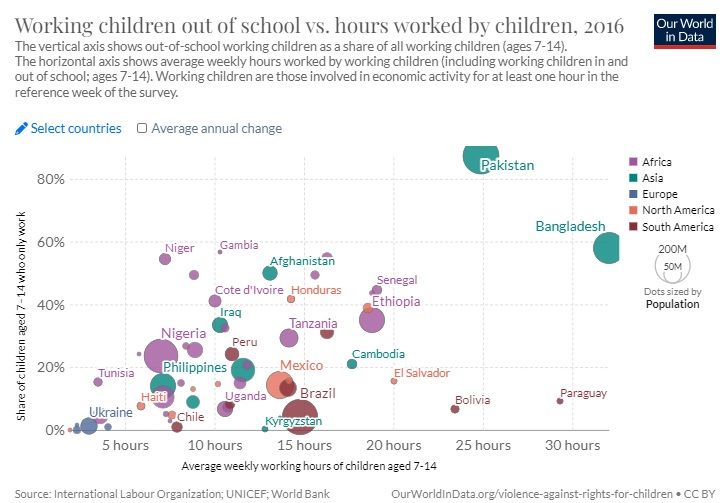

The risk of child labor varies per country and per product. For example, the risk of child labor in bamboo cultivation is smaller than the risk of child labor in cotton cultivation. And child labor is much less common in China than in countries such as Turkey, Pakistan and Bangladesh.

Bamboo

Bamboo cultivation is largely free of child labor. The greatest risk of child labor is seen in Burma/Myanmar, where children are required to cut bamboo for military camps without pay. However, this bamboo is not intended for the textile industry. Fortunately, as far as we know, bamboo for the textile industry is largely free of child labor.

Cotton

Unfortunately, there is quite a lot of child labor in cotton cultivation. The list of countries at risk is long; Argentina, Azerbaijan, Benin, Brazil, Burkina Faso, China (Xingjiang only, mainly forced labor by Uighurs), Egypt, India, Kazakhstan, Kyrgyzstan, Mali, Pakistan, Tajikistan, Turkey, Turkmenistan, Zambia. A number of these countries are well-known production countries of reusable diapers. A number of cloth diapers are produced in Pakistan and Turkey. Reusable cloth diapers made of bamboo and/or polyester that are produced in China do not come from the Xingjiang region and therefore pose a smaller risk than cloth diapers from Pakistan or Turkey, for example.

Textile production

In some countries, textile production is partly done by children. Countries at risk are Bangladesh, Cambodia, China (Xingjiang region, mainly forced labor by Uighurs), Ghana, Pakistan, Vietnam.

Silk

India is a child labor hazard when it comes to silk. Our silk inserts are made in Italy with silk from China.

Source: Bureau of International Labor Affairs

And what about a quality mark?

There are various organizations that are committed to a child labor-free world. A number of quality marks focus (partly) on child labor.

The most common quality marks within the reusable diaper industry are the OEKO-TEX and GOTS quality marks. The OEKO-TEX quality mark has several variants. Made in Green, Standard 100 and Leather Standard for example. The OEKO-TEX quality mark mainly looks at the occurrence of harmful substances in all used parts of an end product. In the case of a diaper, the fabric, but also the elastics and press studs, for example. The Made in Green quality mark also looks at working conditions, including child labor and forced labor. Unfortunately, this quality mark is rarely used. The OEKO-TEX Standard 100 is by far the most common quality mark. Unfortunately, this quality mark does not take working conditions into account.

The GOTS quality mark is a quality mark for organic cotton. This quality mark mainly says something about the creation of a textile product. For example, 95% of the product must consist of organically produced materials if a product wants to carry the 'Organic' label. There must also be a water management plan for the cultivation of raw materials and no genetically modified organisms may be used. All waste water from wet processes (such as bleaching or dyeing fabrics) must be purified. Chemicals used such as dyes must comply with certain basic rules and hazardous substances may not be used at all. In addition, the efficiency of water and energy consumption also plays a role.

GOTS also partly looks at working conditions. Unfortunately, mainly in the production phases of the chain, from fiber to cloth, and from cloth to clothing. There should be no child labor, forced labor or discrimination here. Working conditions must be healthy and safe, working hours acceptable and there must be freedom of association. The sixth version of the standard states that the requirements for working conditions in principle also apply at 'farm level'. However, to some extent given the difficulties in proper monitoring, a 100% guarantee cannot be given.

In any case, with a GOTS quality mark you are much safer when it comes to reducing the risk of child labor. Fortunately, many diaper brands work with GOTS certified materials.

Other quality marks

In addition to the above-mentioned quality marks, there are a number of other quality marks that can be used for textiles and which look at child labor to a greater or lesser extent. As far as we know, these are rarely used in the washable diaper industry. For the sake of completeness, you will find an overview of textile quality marks at the bottom of this blog.

Child labor as a complex problem

Child labor is a very complex problem and therefore a simple solution is not obvious. The diagram below shows how complex the situation is. Child labor is a vicious circle of poverty, a lack of education, illiteracy, no or poorly paid work and therefore poverty again. In many cases, parents of child laborers were also child laborers themselves. To that extent, it is often normal that their children also have to work hard at an early age. Parents are not educated, were child laborers from an early age and earn very little. They spend long days away from home, with their older children having to care for the younger children. Also a form of child labor. The children who work outside the home often earn a very small amount of money and that extra income is essential to keep the family afloat. As a result, the opportunity to go to school is often not even available, regardless of the fact that in many areas there is no training available at all.

Until a few years ago, the response of companies that encountered child labor in their production chain was to immediately stop dealing with the supplier or cotton farmer in question. This does not solve the problem, but rather worsens it. After all, that very small amount of income was also taken away and we would have to work even harder and more to collect the stolen income somewhere else.

Fortunately, it is now the standard not to stop working with a supplier when child labor is discovered, but to work intensively together to improve or solve the problem. Increasing wages for parents and organizing good education (in many cases with free meals for students, to further relieve the burden on parents) in the neighborhood are two of the most important steps in this regard.

Legislation

Dutch and European legislation is coming in the field of International Corporate Social Responsibility (IMVO). This legislation will oblige companies to take steps against child labor. Decision-making on European legislation is constantly being postponed, the Dutch government has decided not to wait any longer and is therefore working on its own national legislation. Presumably, European legislation will only apply to companies with at least 250 or even 1,000 employees. In principle, the Dutch government wants the legislation to apply to every company, including small and medium-sized enterprises (SMEs). The new Dutch law will require that a company can demonstrate that steps have been taken to prevent child labor in the chain. The most important steps are entering into dialogue with your suppliers and mapping the chain. In addition, there must be an action plan to tackle child labor in the chain.

Our approach

Ever since the start of Nappy's.nl, we have been asking potential new suppliers to tell us as much as possible about who they are and how they work. We think it is very important to start a conversation about working conditions. Not only in the field of child labor, but also in the field of good wages and good working conditions for adult employees. We ask for quality marks, agreements made and photos. If we don't feel good about something, we don't do it. Simple statements like those in the introduction bother us, they are dangerous and misleading. Just because something was put together in Europe does not necessarily mean that it is child labor free. And just because something is made in China does not necessarily mean that it was made by children. In fact, child labor hardly occurs in China. The biggest problem in China currently lies in the Xinjiang region where forced labor by Uyghurs is common. We do not sell products that originate in this region. Especially for diapers containing cotton, the risks of child labor are at the front of the chain. In a place where control is extremely difficult; small-scale farms where children are put to work during the harvest period. The fact that the diaper is assembled with cotton in Germany, Hungary or the Netherlands unfortunately does not say enough and is no guarantee of a child labor-free product. And even if the raw materials are free of child labor, there is still a small risk of child labor during production in Europe, especially when it concerns community production or in areas with many refugees.

We are currently in discussions with all our suppliers about this important topic. How transparent is the chain, what do you do to prevent or phase out child labor and do you use quality marks? And to what extent do these quality marks guarantee a 100% child labor-free chain? The responses from suppliers are generally great, almost everyone we speak sees the importance of this question.

We would prefer to split ourselves into thousands of parts to be everywhere at the same time, unannounced and for a longer period of time. From cotton plantation to sewing workshop, at all our brands, at all steps of the chain. But that's impossible. Just like we cannot possibly solve this complex and major problem on our own. The solution lies mainly in a higher wage for parents, in combination with good training where it is needed. That is not within our direct power and establishing good schools is not our expertise. What is possible is to enter into a partnership with a non-governmental organization (NGO) that is worldwide and knows where the problems are. And who also has the resources and knowledge to initiate structural solutions. We have therefore decided to make structural donations to Unicef. In the field of child labor, they are one of the largest active NGOs that try to improve the situation worldwide. They currently have a number of projects running in Turkey, to which we are happy to contribute. They provide training and fight for a living wage. We will donate a fixed amount to Unicef every month for this purpose, from November 2022. In addition, we will discuss with all our suppliers the possibilities of going the extra mile and choosing Fairtrade cotton or another quality mark.

We cannot, dare and do not want to promise you that all our products are free of child labor from start to finish. We opt for transparency and an open mind. We consciously choose to leave open the possibility that there may be a small chance that child labor may occur somewhere at the beginning of a chain. Even though we have no indication of this at the moment. We choose this because it is the only institution that will allow things to improve in the future. We promise that we will do everything we can to detect or prevent any problems. We also promise that if we come across indications of child labor, we will do everything we can to find a sound structural solution together with the supplier in question. We would like to share with you that no worrying situations regarding child labor have come to light at this time and that our suppliers find the use of child labor just as objectionable and undesirable as we do. Only by entering into discussions, devising and implementing structural solutions and working together with influential parties can child labor disappear worldwide. That is our deepest wish.

Overview of textile quality marks alphabetically

Better Cotton Initiative – This quality mark only sets requirements for the cultivation of cotton. It is not an organic quality mark and the use of genetically modified seeds, for example, is permitted. Water policy must be handled sustainably, pesticides must be used at a minimum and the focus must be on sustainability and improvement. Child labor must not be used to get from seed to cotton fiber.

Bluesign – This quality mark sets certain environmental requirements for the end product, in addition, the product must be free of toxic substances. Child labor in the production chain from fiber to end product must be phased out. In theory, this label can also be used if there is still some child labor involved in the production process.

Cotton Made in Africa – This quality mark only sets requirements for the cultivation of cotton and does not look at the further steps in the production chain. The use of genetically modified seeds is prohibited. The land is also not allowed to be irrigated. This quality mark is the only cotton quality mark that requires cultivation based solely on rainfall. Child labor is prohibited and education through training is used, so that farmers can increase their turnover and improve their working conditions. Farmers can also receive financing to purchase fertilizer and seeds.

EU Ecolabel – This quality mark sets environmental requirements for the entire textile production chain. From the cultivation of the fiber to the assembly of the end product in sewing workshops. We even look at the end product itself, which must not wear out too quickly and must have a long lifespan. Child labor is prohibited in the phase from cloth to end product. Working conditions are not included in the earlier steps in the chain. The Tencel fabric used for our Buuh diapers carries the EU Ecolabel.

Fair for Life – Fair for Life is a certification program for fair trade within agriculture, production and trade. The quality mark has a long-term vision and looks at the entire chain. Each step in the chain must meet strict conditions in terms of economy, environment and working conditions. Child labor throughout the chain is prohibited.

Fairtrade - Although the Fairtrade logo mainly appears on food, it also exists for cotton and textile production. There are 18 Fairtrade certified cotton cooperatives, representing a total of more than 46,000 cotton farmers. 75% of Fairtrade cotton is also certified organic. To be allowed to use a Fairtrade quality mark, there are requirements in the field of environment and working conditions. Child labor is prohibited, even in the first steps of the chain. Avo+Cado cotton products, such as the prefolds, are made from Fairtrade cotton.

Fair Wear Foundation – This is more of a code than a quality mark. Members of the Fair Wear Foundation must implement eight internationally recognized labor standards in their factories. Only the production phases of textiles are taken into account, not the cultivation of raw materials. Unfortunately, small companies without substantial own production cannot join the Fair Wear Foundation.

Written by Ilka, owner Nappy's.nl